INTEGRATION GUIDE FOR THE CANON RK F1

CANON RK F1

CONFIGURATION

Default settings when the instrument is shipped from Canon are as follows:

TRANS : OFF

[FMT] : 1

[BAU] : 19200.8N1

You need to set TRANS to ON and FMT to 3.. leave default BAU settings

CRYSTAL

MACHINE UTILITY CONFIGURATION

Set up the Crystal PM Machine Utility using the following instructions: Crystal PM Machine Integration Utility Setup

|

Data Speed: |

19200 |

|

Data Bits: |

8 |

|

Parity: |

Even |

|

Stop Bits: |

One |

|

Flow Control: |

None |

|

Write Response: |

6 |

|

Output: |

Text (.txt) output |

CRYSTAL

CONFIGURATION

Add

the Machine:

1. In Crystal, go to the Records tab

2. In Records, navigate to EHR Settings à Import Machines à Select an open Machine Slot

3. A window will open with a list a of machines, click on “Browse for available machines” at the bottom

4. Choose the machine labeled “Canon RK F1”

5. Browse to the .txt output location (C:/Program Files (x86)/CrystalPM/mach/mach1/mach1.txt)

6. Click open, then leave the Records tab in Crystal and then come back to it (Click on Tasks tab then click back onto records tab.)

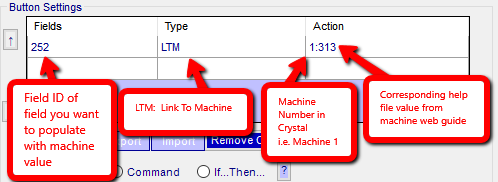

Create the button in records:

1. In Records, navigate to EHR Settings à Edit Medical Record Templates

2. At the bottom of the Edit Fields Window click on “Add New Field”

3. Make the field type to be a button

4. Assign the fields in your template to the corresponding fields from the txt file below:

5. Add field to template and Save Changes

MACHINE BUTTON

MAPPING

ID Data ___________________

1

FileName

2

Date

3

VD

4

OD Raw Data [typically 3 readings]

5

OD SPH

6

OD CYL

7

OD AXIS

8

OD KER INDEX

9

OD K1 mm

10

OD K1 diam

11

OD K1 Axis

12

OD K2 mm

13

OD K2 diam

14

OD K2 Axis

15

OD K Avg mm

16

OD K Cyl

17

OD K Axis

18

OD Rest Cyl

19

OD Rest Axis

20

OS Raw Data [typically 3 readings]

21

OS SPH

22

OS CYL

23

OS AXIS

24

OS KER INDEX

25

OS K1 mm

26

OS K1 diam

27

OS K1 Axis

28

OS K2 mm

29

OS K2 diam

30

OS K2 Axis

31

OS K Avg mm

32

OS K Cyl

33

OS K Axis

34

OS Rest Cyl

35

OS Rest Axis

36

PD